CR(M)250AR SUPERMOTO BUILD

Posted: Mon Apr 11, 2011 11:54 pm

Hey fellas,

Thought it would be a good idea to fill this forum up with builds to try and expand the resources available here.

This is my short term project designed to build up my two stroker skills and to keep me patient while im between built trips to Newcastle to work on my KTMito . (im dieing to get back on the track on any bike!)

. (im dieing to get back on the track on any bike!)

I bought a Honda CRM250AR 1999 from Newcastle 4 months ago, and managed to bring it home to Melbourne recently where I took it for a few rides and diagnosed problems that needed tending to.

first things first...

For those who dont know, the CRM250AR was the production version of the EXP-2 Enduro prototype that used Active Radical Combustions to decrease emmissions.

The bike at low revs and low throttle openings closes and exhaust flap (hondas fancy word por PV) and introduces hot exhaust gases back into the cylinder to become thousands of tiny spark plugs (known as Active Radicals).

Therefore the Spark ignition is no longer required, the engine 'diesels' as it undergoes controlled detonation combustion.

When Undergoing AR combustion the engine purrs steadily without the expecting 'ring-ding-ding' unsteady combustion cycles common in two strokes. its almost akin to a four stroke.

Crank the throttle open and the engine comes to live with potency close to a CR250 honda.

Now that your all up to date with the CRM history, here is the low down on my build progress.

I dont have much spare time so this post might be a bit erratic and not in a particular order but I just dont have the time right now haha please just appreciate it for what it is

The ancient knobbies were removed and replaced with Pirelli Scorpion road tyres.

Forks serviced with fresh oil; more viscous and higher oil level to increase air spring effect toward the end of travel.

preload on shock increased

new brake pads

Fresh brake fluid

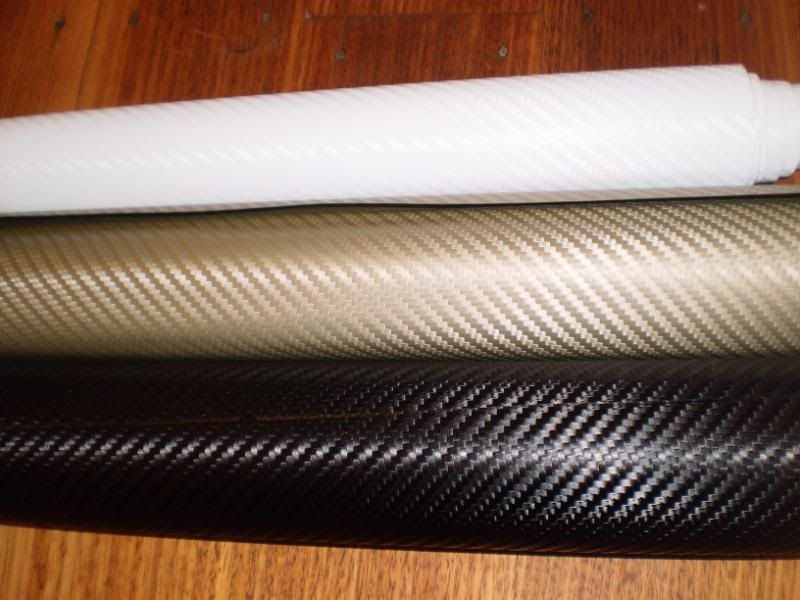

sanded back all plastic panels with wet and dry, I am making replica decals using white and black 3M Di-Noc Carbon Fiber

and am going to prepare the panels to make them nice and shinny using a new product I found called Novus, for plastic polishing (usually pinball machine perspex)

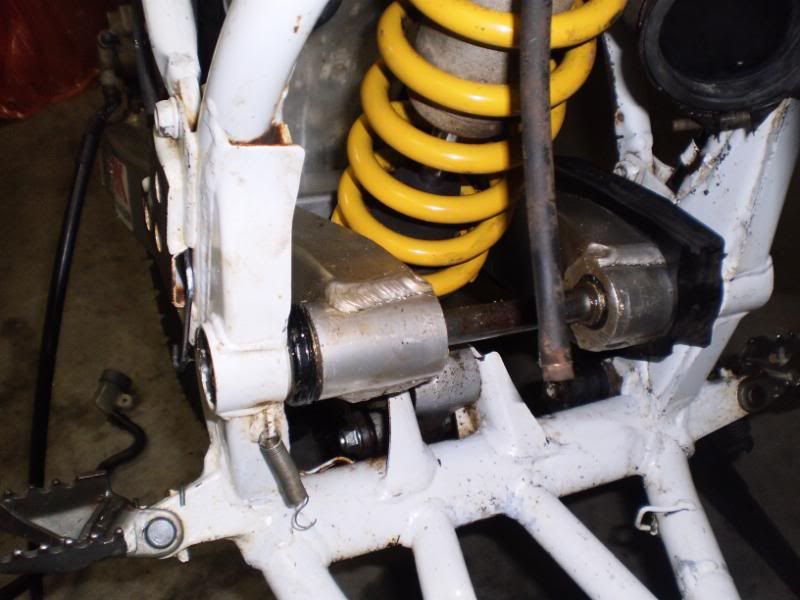

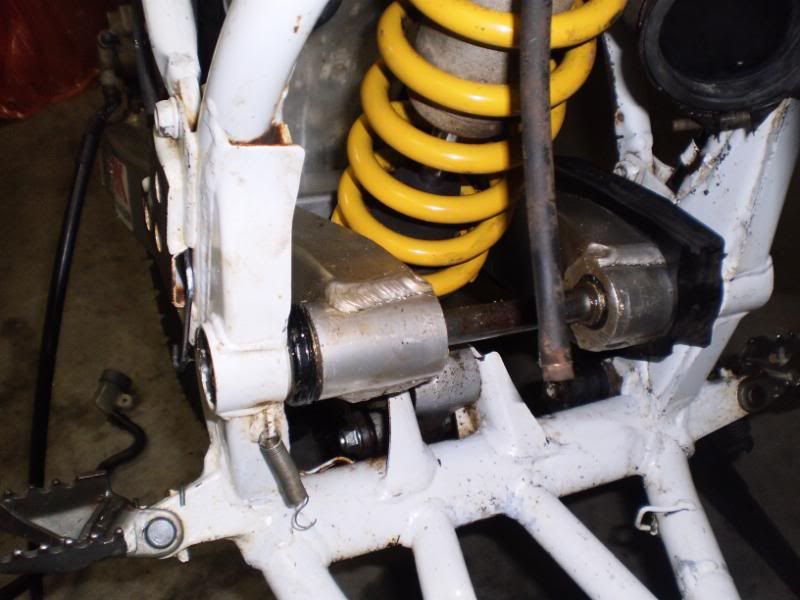

then I pulled the engine out, after 3 weeks of trying to bash out the siezed swing arm pivots. Replaced the swing arm bolt, the two bushes, the four bearings, the four seals and the nut, after covering with heaps of grease

pretty bad hey!

Touched up the frame paint using a paint texta as a primer, and later on I will touch up with a proper enamel and clear coat. just wanted to touch it up and prevent the rust for now.

removed the triple clamps and steering stem, punched out the races and replaced with some new after market bearings.

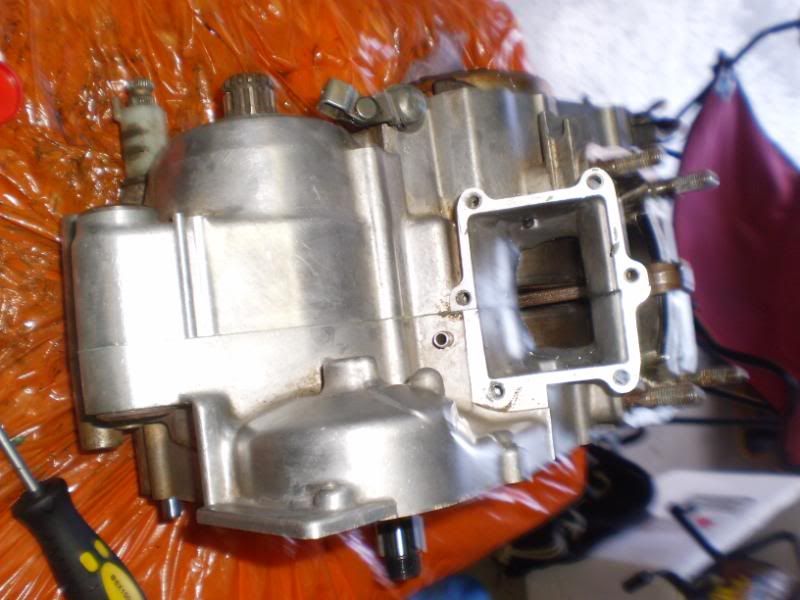

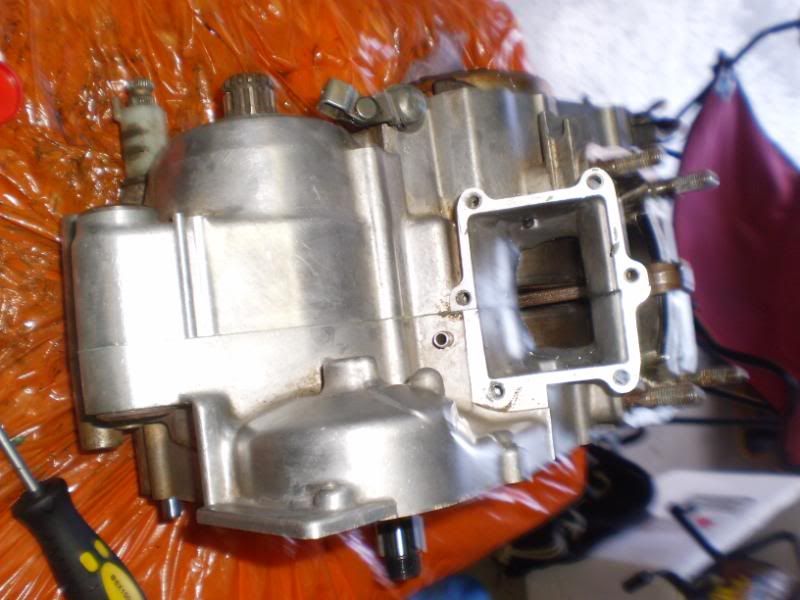

pulled the engine down, left the top end with Lozza after an encounter with airport security that one could only describe as interesting as I tried to go through baggage check with a big lump of aluminium two stroke goodness in my bag.

sanded and repainted the engine covers in a less 'plastic' looking gold

hit the engine cases with a stainless wire brush to remove 10 years of grit.

I was very happy with the brushed aluminium look that I got after a half hour of rubbing.

got a wossner piston on the way to replace the cracked piston that was in the poor girl

Shes also getting all new seals throughout the engine and new crank bearings.

Got a Vforce3 reed intake and am replacing the 32mm PE carb with a PWK38

And modified intake boot to suit the cr250 vforce

The bike already has a pro-circuit pipe and a mugen (honda's version of yoshimura) muffler

aswell as a mugen shaved head and a mugen racing ignition.

I had an issue with a leaking carb warmer line so I removed this with a m5 thread taper, a stainless bolt and some Wurth purple goo

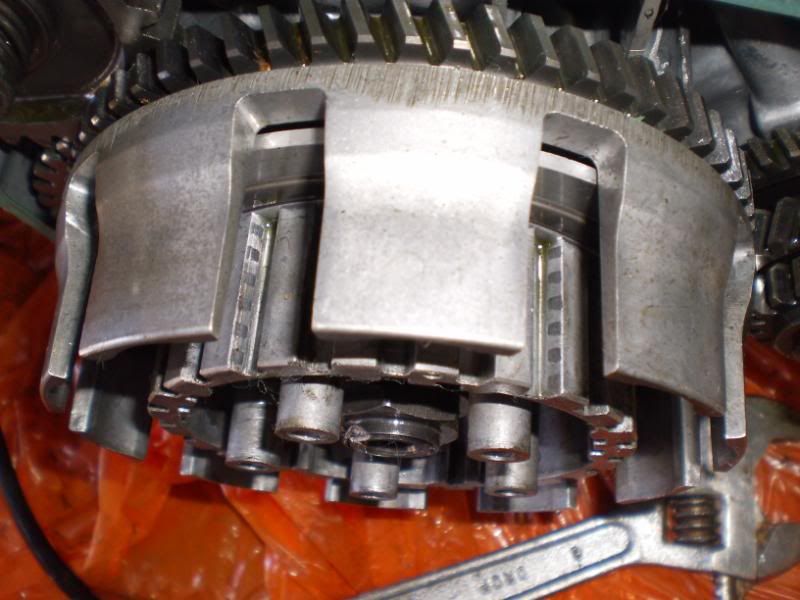

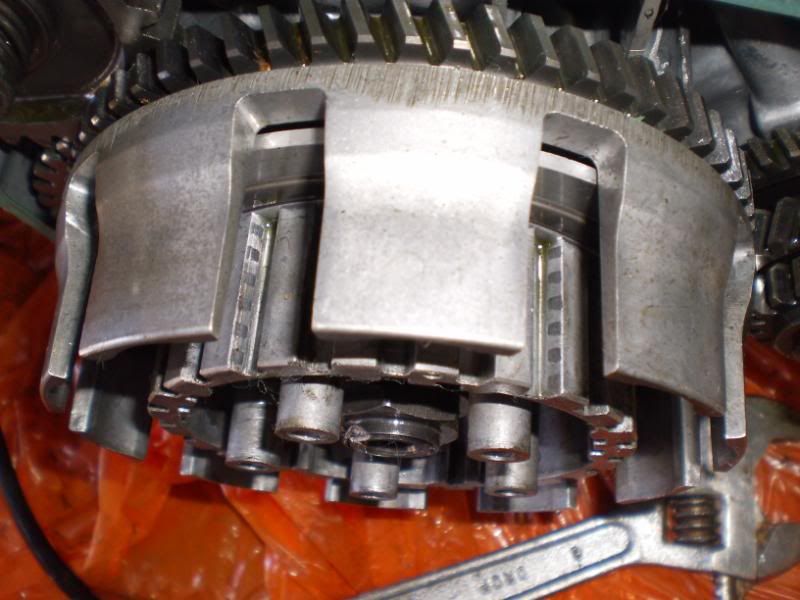

after pulling the clutch apart I found that it was heavily grooved and required filing down to make smooth. should last another 5000ks or so before she needs replacing with a new one.

See the odd scuff marks on the outside of basket, any idea what this is from? Im clueless what caused this? any reason for concern???

In terms of gearing, I am reverting back to the OEM 14/42 gearing which is good for 150kmh as the CRM250AR has an overdrive 6th gear. these are OEM sprockets with a 520 Oring chain.

I should have the bottom end back this week sometime after I sent it to a mate to have the fly wheel pulled, the cases split and the crank bearings pulled. I hope to be able to do this in the future but Im just slowly getting my garage together with the tools I require.

Then she is 100% ready to put back together apart from the top end.

I am hopeing to have her back together and running for a trackday in mid May at Broadford.

Breaking News; Bottom end is done and getting it back tomorrow night!

very good news

Thought it would be a good idea to fill this forum up with builds to try and expand the resources available here.

This is my short term project designed to build up my two stroker skills and to keep me patient while im between built trips to Newcastle to work on my KTMito

I bought a Honda CRM250AR 1999 from Newcastle 4 months ago, and managed to bring it home to Melbourne recently where I took it for a few rides and diagnosed problems that needed tending to.

first things first...

For those who dont know, the CRM250AR was the production version of the EXP-2 Enduro prototype that used Active Radical Combustions to decrease emmissions.

The bike at low revs and low throttle openings closes and exhaust flap (hondas fancy word por PV) and introduces hot exhaust gases back into the cylinder to become thousands of tiny spark plugs (known as Active Radicals).

Therefore the Spark ignition is no longer required, the engine 'diesels' as it undergoes controlled detonation combustion.

When Undergoing AR combustion the engine purrs steadily without the expecting 'ring-ding-ding' unsteady combustion cycles common in two strokes. its almost akin to a four stroke.

Crank the throttle open and the engine comes to live with potency close to a CR250 honda.

Now that your all up to date with the CRM history, here is the low down on my build progress.

I dont have much spare time so this post might be a bit erratic and not in a particular order but I just dont have the time right now haha please just appreciate it for what it is

The ancient knobbies were removed and replaced with Pirelli Scorpion road tyres.

Forks serviced with fresh oil; more viscous and higher oil level to increase air spring effect toward the end of travel.

preload on shock increased

new brake pads

Fresh brake fluid

sanded back all plastic panels with wet and dry, I am making replica decals using white and black 3M Di-Noc Carbon Fiber

and am going to prepare the panels to make them nice and shinny using a new product I found called Novus, for plastic polishing (usually pinball machine perspex)

then I pulled the engine out, after 3 weeks of trying to bash out the siezed swing arm pivots. Replaced the swing arm bolt, the two bushes, the four bearings, the four seals and the nut, after covering with heaps of grease

pretty bad hey!

Touched up the frame paint using a paint texta as a primer, and later on I will touch up with a proper enamel and clear coat. just wanted to touch it up and prevent the rust for now.

removed the triple clamps and steering stem, punched out the races and replaced with some new after market bearings.

pulled the engine down, left the top end with Lozza after an encounter with airport security that one could only describe as interesting as I tried to go through baggage check with a big lump of aluminium two stroke goodness in my bag.

sanded and repainted the engine covers in a less 'plastic' looking gold

hit the engine cases with a stainless wire brush to remove 10 years of grit.

I was very happy with the brushed aluminium look that I got after a half hour of rubbing.

got a wossner piston on the way to replace the cracked piston that was in the poor girl

Shes also getting all new seals throughout the engine and new crank bearings.

Got a Vforce3 reed intake and am replacing the 32mm PE carb with a PWK38

And modified intake boot to suit the cr250 vforce

The bike already has a pro-circuit pipe and a mugen (honda's version of yoshimura) muffler

aswell as a mugen shaved head and a mugen racing ignition.

I had an issue with a leaking carb warmer line so I removed this with a m5 thread taper, a stainless bolt and some Wurth purple goo

after pulling the clutch apart I found that it was heavily grooved and required filing down to make smooth. should last another 5000ks or so before she needs replacing with a new one.

See the odd scuff marks on the outside of basket, any idea what this is from? Im clueless what caused this? any reason for concern???

In terms of gearing, I am reverting back to the OEM 14/42 gearing which is good for 150kmh as the CRM250AR has an overdrive 6th gear. these are OEM sprockets with a 520 Oring chain.

I should have the bottom end back this week sometime after I sent it to a mate to have the fly wheel pulled, the cases split and the crank bearings pulled. I hope to be able to do this in the future but Im just slowly getting my garage together with the tools I require.

Then she is 100% ready to put back together apart from the top end.

I am hopeing to have her back together and running for a trackday in mid May at Broadford.

Breaking News; Bottom end is done and getting it back tomorrow night!

very good news